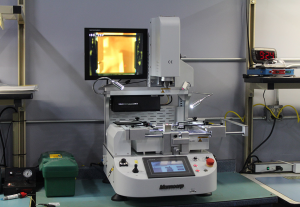

SMT Rework Machine

I.F. Engineering offers a number of contract manufacturing services, the designing and manufacturing RF integrated systems, subsystems, and components, to SMT rework machining for repairing and altering printed circuit boards.

As part of our contract manufacturing services, I.F. Engineering also has SMT rework machining capabilities. We can alter printed circuit boards, repairing or refinishing them. Our technicians can remove and replace defective parts, reinstall parts that were incorrectly placed, or even put in parts that were missing.

Our RW1210 SMT Rework Station not only restores the functionality of the reworked assembly, but also protects all of the parts of the assembly that aren’t being reworked. Thermal stress is kept as low as possible, ensuring that the board is not immediately damaged, and is protected from future damage.

Vapor Degreasing

I.F. Engineering has many capabilities to offer as a contract manufacturer. Not only can we produce quality products and ensure their conformance with quality standards, we also have equipment to clean those products once they’ve been machined.

What is vapor degreasing?

Vapor degreasing is a cleaning process that does not require any water or scrubbing, like usual cleaning processes. Instead, solvent vapors are condensed onto the object being cleaned in order to remove contaminants. As the solvent drips off of the object, it takes the soil with it, leaving behind a clean surface.

The benefits of vapor degreasing

Vapor degreasing has many advantages, especially in industries where precision is key. This method of cleaning results in a superior finish free of contaminants. There is also no risk of cross-contamination, and the objects will dry quickly without any secondary processes.

Vapor degreasing is also a much more economic method of cleaning, as the solvents are recycled within the closed loop process of it. Also, it doesn’t require some of the other things such as heating water, rinsing, or wastewater that other cleaning methods need.